Equipment For Mining Operations | Westpro Machinery

New to Mining? Here are the Most Common Types of Mining

WhatsApp)

WhatsApp)

New to Mining? Here are the Most Common Types of Mining

Mining companies are highly dependent on the reliability of the equipment and vehicles used for mining and transportation of their products. Cloud computing can play a key role in determining how successful a companys operation and management efforts are in maximizing the uptime of machinery and vehicles used in mining, handling, and storage .

The majority of surface mining equipment in the world comes from one manufacturer: . And for good reason. Cat#174; equipment is designed to lower cost per ton by providing productive and reliable performance no matter the application.

Due to the secretive nature of miners and extreme value of cryptocurrency mining equipment, it can be difficult to tell if you live near a huge BTC mining operation. Theres no doubt that as the value of cryptocurrencies continues to rise, we can expect to see more of these monster mining operations unveiled in the near future.

#0183;#32;Surface mining today is characterized by very large equipment (, trucks that can haul more than 300 tons of rock, loading shovels with buckets greater than 36 cubic meters, draglines with buckets greater than 120 cubic meters), and modern technology for planning, designing, monitoring, and controlling operations.

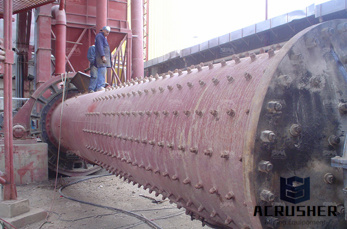

All our products are mineduty. From mining mega projects to pilot operations, Westpro has the capabilities to design and manufacture process equipment for any project scale. Mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores.

Specialised underground mining equipment such as diggers, loaders, and trucks are used to excavate raw materials and transferred to the surface with lifts for future processing. In order to place...

mobile equipment in mine operations. The four mobile equipment audit documents cover: traffic management (Part 1), mining operations and equipment selection (Part 2), surface and underground operations with site deliveries (Part 3), and management of mobile equipment maintenance (Part 4).

Whether for continuous handling of equipment or materials transport, Siemens offers a complete portfolio for continuous mining excavation in opencast mining. Siemens offer focuses on reliability of operations while maximizing output to reduce the costs per extracted ton.

Probably one of the most common pieces of mining equipment, drills are an important part of the underground mining operation. Underground mining is carried out when rocks or minerals are located at a fair distance beneath the ground. But then they need to be brought to the surface.

In an industry where different operations are carried out, various mining equipments are necessary to help you perform the job more efficiently. These are the mining machines youll often

For earthmoving or mining applications, it is imperative to have hauling units. A wide range of tipper trucks and offhighway dumpers serve the purpose of hauling. Depending on the excavator bucket capacity, quantity and density of material to be excavated and hauling distance, various sizes of tipper trucks /dump trucks are deployed.

The ground and noise vibrations are produced during mining operations such as drilling and blasting, movement of mining equipments like shovels, dumpers, drills, dozers, rippers etc. 7. Occupational Health Hazards: Miners working in different type of mines suffer from asbestosis, silicosis, black lung disease. Remedial Measures:

WhatsApp)

WhatsApp)