Grinding Mill at Best Price in India

Grinding Media: Mills may be charged with ceramic, steel and alloy steel grinding media. These are spherical or cylindrical in shape and range from 6 mm to 100 mm in size. Capacity : 210

WhatsApp)

WhatsApp)

Grinding Media: Mills may be charged with ceramic, steel and alloy steel grinding media. These are spherical or cylindrical in shape and range from 6 mm to 100 mm in size. Capacity : 210

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

offers 370 large capacity grinding mill products. About 10% of these are Mine Mill, 8% are Flour Mill, and 8% are Grinding Equipment. A wide variety of large capacity grinding mill options are available to you, such as warranty of core components, condition, and local service location.

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM D to LM D), with table diameters from 1,200 to 2,000 mm. Larger mills with two, three and four rollers and modular structures (LM D to LM D), with table diameters from 2,100 to 4,300 mm.

#0183;#32;1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of

limestone, pharmaceuticals, pigment blends, plastics, rocks, roots, shale, seeds, slags, soil, teeth, wood, etc. To provide safety and prevent sample loss, the grinder operates only when the cover is latched in place. Supplied with a (6ft) 3wire cord and grounded plug.

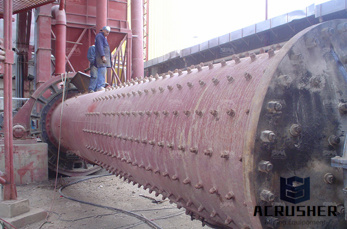

The tumbling grinding mill (Fig. 2) is the solution to the problem of applying a relatively small fracture force to a large number of particles. Such mills are cylinders, rotating about the axis, containing a tumbling grinding media, which produces predominantly shatter fracture (because of the relative high energy intensity) as the mineral stream flows through the mill.

It uses the experimental small mill to compare the material to be tested with the standard sand to achieve the specified fineness value and calculate the time of grinding. Moisture of raw material As for the dry grinding method, the moisture of raw material can affect ball mill capacity and quality.

Disadvantages of Hammer Mill. 1. Not recommended for the fine grinding of very hard and abrasive material due to excessive wear. 2. Not suitable for lowmelting sticky or plasticlike material due to heat generation in the mill head as a result of mill fouling. 3. The mill may be choked if the feed rate is not controlled, leading to damage. 4.

The high unit capacity SAG mill/ball mill circuit is dominant today and has contributed toward substantial savings in capital and operating costs, which has in turn made many lowgrade, hightonnage operations such as copper and gold ores feasible. Future circuits may see increasing use of high pressure grinding rolls (Rosas et al., 2012).

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Average grinding capacity*: ca. 25 g / s Small hopper (capacity 500 g / lb) Alignment Tool *Depends on the grinding goods and the chosen degree of fineness. With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill SR 300 is intended for universal use:

M. G. Scientific Traders Offering LABGO Stainless Steel Ball Grinding mill, 35 Kg, Capacity: 100 Capsule at Rs 24500/piece in Ambala, Haryana. Read about company. Get contact details and address | ID:

Do you need a quick estimation of a ball mills capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for tonnage a product P80 size? Use these 2 tables to get you close. No BWi Bond Work Index required here BUT be aware it is only a crude approximation for most soft ores from F80 1 cm to P80 700um. Ball mill design power example

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000

Price : Get Quote MOQ : 1 Piece(s) Brand Name : Condition : Good Capacity range : 1 MT/H to 40 MT/H Feature : Swinging Hammers,Four Time reversible hardened and shaped for best grinding efficienc,Simple feeding Product Name : Hammer Mill Our quest for excellence has inspired us to design and develop efficient Hammer Mill . Designed to perfection, comprises of two functions such as grinding

grinding mill grinding capacity calculation. grinding mill power calculation. grinding mill power calculation grinding mill power calculation. Mill (grinding) A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting To calculate the needed grinding work against the grain size changing three halfempirical mo. Chat Online ; ball mill calculations

Grinding media is grinding feed; High capacity (short retention time) Sensitive to feed composition (critical size material) SemiAutogenous Grinding (SAG) Mill. Wet or dry; Higher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball 125 mm) High

WhatsApp)

WhatsApp)