Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving

HeNan Yu Hui can supply any type of ball mill machine, If you are interested in our ball mill,cone ball mills, EnergySaving Ball Mill,welcome to contact us.

WhatsApp)

WhatsApp)

HeNan Yu Hui can supply any type of ball mill machine, If you are interested in our ball mill,cone ball mills, EnergySaving Ball Mill,welcome to contact us.

#0183;#32;XMQ series conical ball mill in pioneers is a metallurgical, geological, chemical, building materials and other departments of the testing laboratory for min...

Mining in Egypt has had a long histories that goes back to predynastic times. Egypt has substantial mineral resources, including 48 million tons of tantalite (fourth largest in the world), 50 million tons of coal, and an estimated million ounces of gold in the Eastern Desert. The total real value of minerals mined was about #163;E102 million (US million) in 1986, up from #163;E60 million

Descrption. GTEK XMQ series Cone Ball Mill is a laboratory grinding equipment for wet grinding of ore (150#215;50 cone ball mill can also be used for dry grinding). It is suitable for mineral feasibility study of laboratories in schools, research institutes and ore beneficiation cone ball mill can also be used for grinding of a small amount of material in the field of metallurgy

XMQ Series Cone Ball Mill is a lab grinding equipment for wet fine grinding of ore (150 #215; 50 Cone Ball Mill also can be used for dry grinding). It is applied in labs for processing and fine grinding for the industry of metallurgical, building material, chemical, light industry, coal, water electric power, agricultural, artificial heavy concentrate in geological testing, mineral processing, etc.

Mining Industry in Egypt : a market analysis about Metal Ores in Egypt, more than half of a company''s revenues go to the Egyptian government. Welcome in the elnasrmining co. Welcome For you In The El Nasr Mining Company The begest Company For Mining In Egypt.

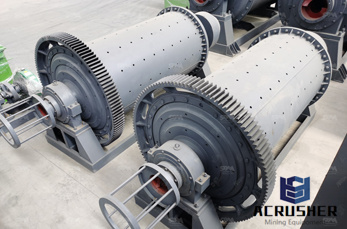

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

ROLLER MILL diagram Egypt Crusher Grinding Mill,CCM Grinding Mill Mineral Mining Machine. diagram of vertical roller mill Coal processing crush plant used in Ecuador you tube working principle of vertical roller millsKefid |

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

Cone Ball Mill. The cone ball mill is the material being broken,the cone ball mill is the material being broken,the key equipment for next used in cement, Portland products,new building material, refractory material, fertilizer,black and nonferrous metal ore dressing and glass ceramics production industry, etc,for all kinds of ores and other materials doing dry or wet grinding.

The mill was built to process 7,000 tonnes per day, and includes a threestage crushing plant, gravity circuit, ball mill, flotation cells and leaching facilities. Also included in the Assets are conveyors, metallurgical and chemical fire assay laboratories, a water treatment plant, full electrical circuitry including generators, and a number of spare parts for the ball mill and crushers.

WhatsApp)

WhatsApp)