(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

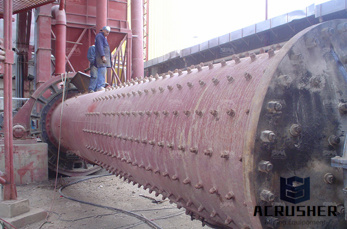

Ball mill is a cylindrical device that used to grind and blend raw materials and it rotates around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

WhatsApp)

WhatsApp)

Ball mill is a cylindrical device that used to grind and blend raw materials and it rotates around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

plant ball mills grinding efficiency (Fig. 1). The functional performance parameters mill grinding rate through the size of interest, and cumulative mill grinding rates from both plant and smallscale tests are applied to this task. A plant media sizing methodology, and

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350...

Forged steel balls; P=s=/m3 cast steel balls P=/m3; rolling steel balls P=/m3; steel segments P=/m3_filling ratio of grinding medium, When wet grinding: lattice ball mill pi = 40% 45%; overflow ball mill phi = 40%; rod mill phi = 35%.

Ball Mill Design/Power Calculation

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

The calculation formula is below: B the grinding balls diameter, mm; A the correction factor (for grinding balls A = 20,17; for cilpence A = 18,15); F the feedstock grain size in 80% of the material, m; K the grinding correction coefficient (for wet grinding 350; for dry grinding 355);

Wet Grinding Ball Mill Grinding Media Calculation. 12 grinding ball mill load calculation formula in nigeria. Whatever your requirements you ll find the perfect serviceoriented solution to match your specific needs with our are here for your questions anytime 24/7 welcome your consultation.

Wet Ball Mill Tourque Calculation. Ball Mill Drive Motor Choices. The torque and time requirements of the mill with the ball charge will set the magnitude and time of the inrush current during mill starting the inertia for this mill reflected to the motor shaft is calculated to be 24300 ftlbs2 the time to accelerate the mill to the design speed is given by the following calculation time wk2x

grinding media loading calculation for ball mill. Calculate and Select Ball Mill Ball Size for Optimum Grinding. Aug 02 2013 #183; In Grinding selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do.

2 #0183;#32;The Wet Grinding Ball Mill market was valued at Million US in 2018 and is projected to reach Million US by 2026, at a CAGR (Compound Annua...

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In todays global markets, expanding mining groups are trying

To participate in the 911Metallurgist Forums, be sure to JOIN amp; LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone elses

Wet Ball Mill = kg kWh = (A ) ; Dry Ball Mill = kg / kWh = i ; Replacement Ball Size. Rowland and Kjos proposed the use of their equation for the determination of the initial and replacement media size. Azzaroni (1981) and Dunn (1989) recommended the use of the following expression for the size of the makeup media:

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges

Grate discharge Wet Overflow discharge Wet Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure

Wet Grinding Ball Mill Grinding Media Calculation. 12 grinding ball mill load calculation formula in nigeria. Whatever your requirements, you ''ll find the perfect serviceoriented solution to match your specific needs with our are here for your questions anytime 24/7, welcome your consultation.

WhatsApp)

WhatsApp)