(PDF) Overview of Mineral Processing Methods

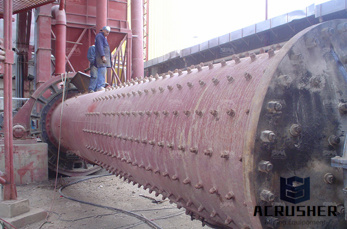

Leaching : M ethod of extraction in which a solvent is passed through a mixture to remove some . of size reduction methods involved in mineral processing using crushing equipments.

WhatsApp)

WhatsApp)

Leaching : M ethod of extraction in which a solvent is passed through a mixture to remove some . of size reduction methods involved in mineral processing using crushing equipments.

processing machinery mobile mineral gold ore extraction equipment,These five illustrated flowsheets fully described in the article Small Gold Ore Processing Plants follow a natural sequence These start with a very simple Flowsheet AA and then by the addition of the more extensive equipment it is possible to take care of slight changes in the ore as well as improve recovery The following

gold ore processing and concentration equipment. Gold Extraction and Recovery Processes. Various methods such as gravity concentration flotation panning pyrometallurgy cyanidation etc are available for the extraction of gold metal from its ores. Amongst these methods cyanidation is the most common method used in the leaching of gold from the ore.

Mineral Processing EPC+M+O. Xinhai concentrates on providing the Turnkey Solution for Mineral Processing Plant, that is research and design complete equipment manufacturing and procurement commissioning and delivery mine management mine operationquot;

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of

Mineral processing ore gold extraction equipment. Gold Ore processing plant Manufacturer India. Gold Ore Processing. Star Trace''s range of services covers all processes needed for the recovery of gold, from Ore to Dore bar and So on. Converting runofmine (ROM) ore into saleable Gold

Of all the methods of extracting gold amp; processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery

Mining equipment, its performance and availability, occupies a pivotal position in the mining process and determines the performance of mineral extraction and processing operations. The mining industry has gone through impressive changes during recent decades in machine size and unit investment, in very high asset utilisation and in the resulting demand for record production.

With the rising price of gold and the limited amount of mineable land, people are now focusing on the recovery of fine gold. Some rivers of the world have been sluiced as many as 6 times, yielding profitable gold each time and demonstrating that traditional sluices can have very poor recovery. Gold Processing Equipment like the IGR500 focuses on the recovery of the Fine Gold

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified.

Gold Mining Processing Equipment Alibaba. Alibaba offers 5704 gold mining processing equipment products. About 57% of these are mineral separator, 19% are other mining machines, and 6% are crusher. A wide variety of gold mining processing equipment options are available to you, such as gravity separator, flotation separator, and magnetic separator.

Korean Gold Mineral Processing Machinery. Gold milling machine and price in south korea 911MPE has small gold mining equipment for sale and specifically mineral processing equipment Our equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics 911MPE offers gold mining equipment as well as processing equipment

Metallurgical processing of metalliferous ores in general and gold ores in particular, consists essentially of three stages, often colloquially referred to as: Bashing (crushing); Mashing (grinding); and; Hashing (extraction/recovery) In the context of flowsheet selection, the bashing and mashing stages are

Xinhai gold extraction equipment can efficiently seperate gold and gangue by all slime cyanidation(CIP) method, it will bring low cost and high benifits. Group Web. WearResistant Rubber; Mineral Processing EPC and Equipment. Tel: 0086 Email: marketing

China Mineral Processing Small Scale Gold Mining Equipment . China Mineral Processing Small Scale Gold Mining Equipment / Mobile Gold Machine, US 3000 15000 / Set, New, Gravity Separator, 50T/ from Qingzhou Hengchuan Ore Machinery Co., Ltd. . provide the video or send the whole assembled machine.

WhatsApp)

WhatsApp)