Discrete Element Method Computational Fluid Dynamics

Discrete Element Method Computational Fluid Dynamics Modelling of Flow Behaviour in a Stirred Mill Effect of Operation Conditions

WhatsApp)

WhatsApp)

Discrete Element Method Computational Fluid Dynamics Modelling of Flow Behaviour in a Stirred Mill Effect of Operation Conditions

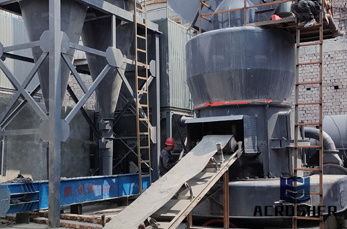

Stirred mills are increasingly used in the mineral industry for a range of milling duties from fine to coarse grinding. This work investigated the particle and fluid flow in a stirred mill using a combined discrete element method (DEM) and computational fluid dynamics (CFD) approach.

qualitative analysis of the screw liner wear prediction in vertical stirred mills by the discrete element method November 2018 Conference: 11th International Comminution Symposium (2018)

Keywords: ball mill, discrete element method, liner wear . REFERENCES [1] D. Boemer, Discrete Element Method Modeling of Ball Mills Liner Wear Evolution, Masters Thesis, University of Li#232;ge (2015).

#0183;#32;ConwayBaker et al. [] studied the effect of the impeller design on the media motion inside a vertical stirred mill by using Positron Emission Particle Tracking (PEPT).Three impellers were tested: a flat blade, a pin type and down pitched impeller. This work highlighted how the impeller strongly influences the upper and lower recirculation loops inside the mill, and consequently, the packing

Discrete Element Method (DEM) Contact Models Applied to Pavement Simulation Bo Peng Thesis submitted to the faculty of the ia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Master of Science In Civil Engineering Linbing Wang Montasir Abbas Cristian Druta June 18, 2014

Double screw reactor Horizontal stirred bed reactor Vertical stirred bed reactor Brown and Brown (2012) Lago et al. (2015) Developing an Discrete Element Method (DEM) A. B., amp; Horio, M. (2008). Finite element modeling of the transient heat conduction between colliding particles. Chemical Engineering Journal, 139(3), 510516. USDA REE

In addition to the measurements the ball motion was simulated using a three dimensional Discrete Element Model (DEM). An attempt was made to account for mill feed via altered friction coefficients. Correlations of the DEM results and experimental findings at different operating conditions show a

2015. The Isamill is a horizontal stirred media mill used for fine and ultrafine grinding. Discrete Element Method (DEM) simulation has been used in this paper to study the behaviour of the media and the collisional environment in a full industrial scale Isamill.

#0183;#32;The present work takes advantage of a mechanistic mill model originally developed for ball mills and the discrete element method (DEM) to simulate breakage in a vertical stirred mill. Data from a batch mill, in which two materials were tested (copper ore and limestone), served as the basis for fitting selected material parameters, whereas the remainder were used as default.

Modelling of physical interactions between pulp, been modelled for dry grinding with a combination of discrete element method (DEM) or smoothed particle hydrodynamics (SPH) together withthe finite element method can as well be applied to dry or wet stirred media mills

#0183;#32;DOI: / Corpus ID: . Discrete Element Modelling of Particulate Media inproceedings{Wu2012DiscreteEM, title={Discrete Element Modelling of Particulate Media}, author={C. Wu}, year={2012} }

Micromechanical aggregate properties are correlated with stress conditions during the dispersion process in a stirredmedia mill. The fracture energy distribution of the aggregates measured via microcompression tests is compared with the stress energy distribution in a stirredmedia mill determined by CFDdiscrete element method simulations and by an analytical model.

Table 1 Variable Used in Published Stirred Mill Power Models STIRRED MILL DEM SIMULATIONS The advent of the discrete element method (DEM) and its introduction to the modelling of mineral processes opened the door to exploring in yet greater detail the dynamics of these systems. This has been successfully demonstrated through modelling of

In paper E, coupled nite element, DEM andPFEM models are used to model the physical interactions of grinding media, slurry andmill structure and in a stirred media mill. The ndings in the present thesis support theestablishment of particlebased numerical methods for modelling granular material owin a number of dierent applications.

Discrete Element Method Modeling of Ball MillsLiner Wear Evolution by Dominik BOEMER Submitted to the Department of Mechanical Engineering on June 4th, 2015, in partial fulllment of the requirements for the degree of Master of Mechanical Engineering Jury Prof. Dr. Ir. JeanPhilippe PONTHOT University of Li#232;ge Academic supervisor

Stirred Mill Discrete Element Modelling 2015; Stirred Media Detritor SMD1100E Circuit Animation YouTube. Oct 06, 2015#183; Published on Oct 5, 2015 The Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products.

particle nite element method for transient granular material ow: modelling and validation. To be submitted. Paper E: S. Larsson, B. P alsson, M. Parian and P. Jons en. A novel approach for modelling of physical interactions between slurry, grinding media and mill structure in stirred media mills

WhatsApp)

WhatsApp)