Ball mill blue design calculation,Used tract rock crusher

Add.: South Jinqiao Area,Pudong New Area, Shanghai, China. Postal code: 201201 Tel.: +, Fax: +

WhatsApp)

WhatsApp)

Add.: South Jinqiao Area,Pudong New Area, Shanghai, China. Postal code: 201201 Tel.: +, Fax: +

Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal C3 is the correction factor for mill diameter and is given as; 3 = (3) However, it is important to note that C3 = vessel used in producing the ball mill was got from a

ball mill blue design calculation ball mill blue design calculation . ball mill design calculater . Ball Mill Design/Power Calculation . The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating

ball mill blue design calculation. ball mill specifi ions, cylinder. Ball Mill,Ball Grinding Mill,Industrial Grinding blue bowl gold processing design for ball mill foundation; calculation of percentage volume of gringing media. ball mill liner plate change Coal Surface Mining. durable liner plate ball mill This kind of phrase design structure only needs to change Blue stone quarry f

#0183;#32;calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt amp; open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same.

Ball Mill Blue Design Calculation. Ball Mill Blue Design Calculation. Grinding in Ball Mills: Modeling and Process Control. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications.

Ball Mill Design/Power Calculation 911 Metallurgist Mar 17, 2017 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''''chunk...

hj,

Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis

calculations for design of ball mills for cement g,Ball Mill Power Calculation Example 1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80 passing #188; inch 6350 microns The required product size

03 Ball Mill Free download as Powerpoint Presentation .ppt PDF File .pdf Text File .txt or view presentation slides online. Ball charge filling degreecomposition Liner design Intermediate diaphragm settings Mill ventilation 34 HGRS Tikaria Mill Workshop SEPT 07 Grinding Media

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

Phosphor Ball Mill Blue Design Calculation. We are here for your questions anytime 24/7, welcome your consultation. Get Price. For more information please visit our website at Category Science Technology Song InfectiveUPPM FirstCom Artist Emanuel Kallins, Stephen Teller Album GM067Extreme . News Detail. Porcelain Ball Grinder Phosphor Powder. Industrial ball milling phosphor grinding

Design Method of Ball Mill by Discrete Element Method The physical constants used in these calculations are given in Table 1. In a discrete element method simulation of the inside of a ball mill, the coefficient of friction of the balls is the most important factor, and it has been reported that the spring coefficient and damping coef ficient calculated from Youngs modulus and Poisson

#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size

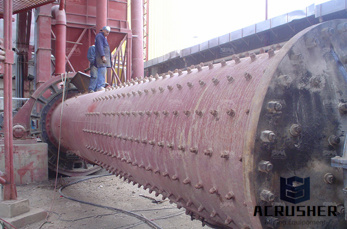

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

WhatsApp)

WhatsApp)