How is gold mined?

Hardrock Mining Techniques|Underground Mines|Minings

WhatsApp)

WhatsApp)

Hardrock Mining Techniques|Underground Mines|Minings

13/07/2018#0183;#32;In this adventure in hard rock mining, I explore the spooky Blue Chip mine and collect 500 lbs of quartz vein material from the spot Dave told me to dig. Thi...

How to Recognize Hard Rock Gold Ores. September 2017 by Chris Ralph. I regularly get inquiries along the line of: Hey, I found this rock, and I think it might be gold ore. How can I tell? Prospectors are always on the lookout for goldbearing rocks that may be the source of any nearby placer gold.

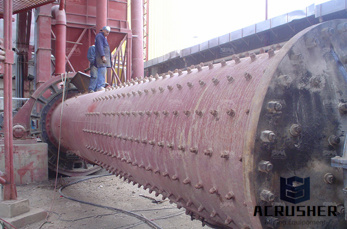

Gold Mining Equipment List. Making a complete list of gold mining equipment starts with defining the type of gold mining you are doing and the budget you have at your disposal. The type of mining relates to hard rock, eluvial, or placer; alluvial deposits. The capital budget you have to invest in buying your equipment with dictate the scale at which you want to mine and influence the longterm operating costs of your

1. Mining open pit and underground. To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers. Dump trucks haul the rock to the primary crushers in the open pit or to the ore stockpiles from

Hard rock gold mining extracts gold in rock instead of fragments in loose sediment, producing most of the gold in the world. Openpit mining is sometimes used, for example in central Alaskas Fort Knox Mine. Barrick Gold Corporation has one of the largest openpit gold mines in North America located on its Goldstrike mine property in north eastern Nevada. Other gold mines use underground mining where

Processing Hard Rock Gold. Processing Hard Rock Gold; Hard Rock Mining Gold and Silver Ore and processing it. The main problem for individuals or small groups interested in hard rock gold deposits is the high capital costs both for the mining equipment to dig and remove the rock as well as the equipment to crush and process hard rock ore in order to extract the gold from its solid rock enclosure.

Removing the goldbearing rock from the ground is just the first step. To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravel.

Hard rock mining is the process of using open pit or underground mining tunnels to retrieve the gold from the rock. This method of gold mining is responsible for recovering most of the worlds gold supply. Byproduct mining is related to hard rock mining in that open pit or underground mining tunnels are used.

MLI Mining utilize the APT GroundBreaker range of equipment; the JC25, JCRD15 and GoldKacha concentrator. Installation, commissioning and production was achieved within 3 days of equipment arrival on site and with the assistance of APT technicians achieved full production of 30 tonnes a day within 7 days. Gold recovery was achieved on day 1.

Hard Rock Mining. Hard rock mining is the process of gathering rocks with gold veins and using large tools to remove the gold. This type of mining is most commonly used today.

WhatsApp)

WhatsApp)