The energy efficiency of ball milling in comminution ScienceDirect

Factors Affecting Ball Mill Grinding Efficiency

WhatsApp)

WhatsApp)

Factors Affecting Ball Mill Grinding Efficiency

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this

In a second approach, comminution efficiency is based on comparing the energy to produce some size distribution parameter of the product from ball milling with that by singleparticle breakage. For both materials, dry ball milling efficiency was found to be in the range of 25%.

Factors Affect Ball Mill EfficiencySBM Industrial, Factors Affect Ball Mill Efficiency There are various factors affect ball mill efficiency, such as properties of raw material, feeding size, size and proportion of grinding balls and so on And these factors are not mutually independent, they

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill

Grinding efficiency ball aiddaeuhe factors affecting the efficiency of ball mill grinding there are many factors influencing the grinding efficiency of ball making get price the influence of mill speed and pulp density on the grinding between the balls in the mill, is known and we are then able to calculate the factor volume pulpvolume voids between lux, j and clermont, b.

factors affecting the efficiency of ball mill. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher,

The practical limit to ball mill product fineness is considered To determine mill power draw characteristics and capabilities for rod, ball and design vportable stone crushing machinesariables and operating conditions related to ball mill grinding efficiency. Synopsis. Ball mills are usually the largest consumers of energy within a .

Factors Affect Ball Mill Efficiency. There are various factors affect ball mill efficiency, such as properties of raw material, feeding size, size and proportion of grinding balls and so on. And these factors are not mutually independent, they all have effect on each other.

Factors that Effect on the Efficiency of Ball Mill Ball mill is one of the most important crushing and grinding machines in the ore dressing plant, but its energy consumption is the highest in the ore beneficiation production are two types of grinding methods for a ball mill

#0183;#32;Schellinger''s calculated ball mill efficiency, in dry or wet ball mill grinding, ranges between 10% and 19%, with the higher figure occurring at the optimal mill loading. In terms of the Brace and Walsh surface free energy of quartz, his results give a ball mill efficiency that is less than %.

Factors Affect Ball Mill Efficiency. There are various factors affect ball mill efficiency, such as properties of raw material, feeding size, size and proportion of grinding balls and so on. And these factors are not mutually independent, they all have effect on each other.

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this

What Factors Have Much Effect On The Efficiency Of Ball Mill What Factors Have Much Effect On The Efficiency Of Ball Mill. A ball mill is mainly used to grind different minerals and other materials in the industries of ore beneficiation, construction materials and chemical engineering. there are two types of grinding methods for a ball mill: wet grinding and dry grinding. the ball mill is the

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account. As well, mills with different

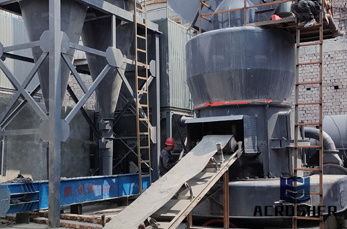

The ball mill equipment is mainly used for grinding and the industry that needs to be floured, and it plays a very important role in China''s basic industry. It plays an important role in the processing of various industrial raw materials in the production line. In the operation of the ball mill, work efficiency has certain factors.

Factors Affecting the Efficiency of Ball Mill . Topics: Iron, Crusher, Ferrous Pages: 2 (439 words) Published: April 2, 2012. Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new

#0183;#32;Mill installed correctly, a good maintenance, optimization operation is to ensure that the mill high production, high operation efficiency, high quality and low consumption of necessary conditions. First must make the pledge that we shall have higher operation rate and low consumption of the necessary conditions. Availability is measured index of grinding machine is in

WhatsApp)

WhatsApp)