Longer Processing Plant Closures Creating Dire Situation

Apr 13, 2020#0183;#32;According to Farm Journals Pork, the South Dakota plant is one of the largest pork processing facilities in the, providing nearly 130 million servings of

WhatsApp)

WhatsApp)

Apr 13, 2020#0183;#32;According to Farm Journals Pork, the South Dakota plant is one of the largest pork processing facilities in the, providing nearly 130 million servings of

Plant Manager at Ag Processing, Inc. St Joseph, MO. Katie Glasnapp. Katie Glasnapp Project Manager at Ag Processing Inc. Eagle Grove, IA. Bowie Ivie. Bowie Ivie Plant Manager at AGP Lariat TX.

Oct 20, 2014#0183;#32;Nature of Gold: The surface of a gold particle will typically be dissolved at a rate of around #181;m of surface depth per hour in a cyanide leach. For large gold particles and nuggets, this is too slow to be fully dissolved in a typical processing plant. Much simpler and less expensive gravity methods are available to recover this gold.

Ag and Rural; Life amp; Style. The sale includes the 350,000 tonnesperannum processing plant, tailings dam, mining leases, property rights and permits, and a 593hectare mining lease covering

Apr 13, 2020#0183;#32;According to Farm Journals Pork, the South Dakota plant is one of the largest pork processing facilities in the, providing nearly 130 million servings of food per week and employing 3,700 people. Its also a major plant for pork producers, as more than 550 independent family farmers supply the plant.

ABERDEEN, Citing good timing for the region''s soybean growers, Ag Processing Inc. held the grand opening for its soybean processing plant in Aberdeen on July 17.

MEGAMINER#174; Semistationary and stationary gold mining plants, gold Processing plants, with capacity range of 52000 Tons/Hour, designed for application of Alluvial gold mining, Hard Rock gold mining projects, other metals and minerals mining. More details in MEGAMINER#174; plants section.

Montana Ag Network: New Processing Plant Good News for Sheep Producers. By: Russell Nemetz MTN Posted at 7:15 AM, Sep 03, 2020 . and last updated 202009

As deposits with free, coarse gold were depleted and the volume of mining increased, process flowsheet design became more and more complicated. Processing plants are designed according to metallurgical tests performed on composite samples and the range of recoveries is explored by testing composites for variability.

manufacturing plant is given in Figure Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is

Ag Gold Processing Plant Stone Crushing Equipment The building aggregates equipment of Aamp;C includes not only a series of single equipment of coarse crushing, intermediate and fine crushing, sand making and shaping, but also a batch of standardized design products of production line on the basis of many years of experience.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore

Seven agricultural processing plants across Mississippi, including poultry companies Koch Foods Inc. and Peco Foods Inc., were raided Wednesday after the Immigration amp; Customs Enforcements (ICE) Homeland Security Investigations (HSI) executed multiple federal criminal search warrants as part of an ongoing HSI worksite enforcement criminal investigation.

Ag Notes Archive 614 2020 Cercospora Review 613 Tips for Maximizing PrePile Payment 612 Cercospora Leafspot Management Notes 611 Whats Your Waterhemp Plan? The Best Defense is a Good Offense 610 Variety Selection amp; OVTs 609 Managing Unharvested Beets

6,000 10,000 TPD CRUSHING/GRINDING CIRCUIT GOLD PLANT with 32'' x 12'' SAG Mill, '' x 28'' Ball Mills, 54quot; x 74quot; Gyratory, 7'' SH HD Cone, Rock Breaker and More. Manufacturer: ALLIS CHALMERS Inventory ID: 18CVI01

May 01, 2020#0183;#32;Bednarz helped facilitate the establishment of the Delta Agriculture Partners processing plant in Slaton. After 26 years of farming, Bednarz turned to the idea of growing hemp and toured the Delta Ag facility in Colorado where theyve been in operation since 2016.

Jan 11, 2019#0183;#32;Nestled in Kuna, Ido, is CS Beef Packers, a meat packing plant built in Beef offers beef harvesting, fabrication, rendering, and hide processing. The facility was built following the formation of CS Beef Packers LLC in 2015, as a result of a partnership between Caviness Beef and JR Simplot Co.. Last year, I participated in a tour of the facility with the Ido Cattle Association and

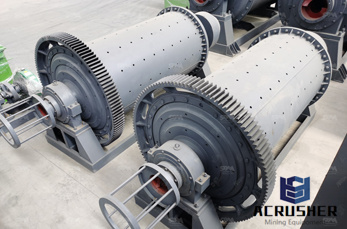

Shunzhi Ball Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new buil...

This plant will provide a large and new market for those soybeans. VALUE ADDED: Soybean oil and meal will be produced at the new Ag Processing Inc processing plant in Aberdeen, AGP is the largest cooperative soybean processing company in the world and a leading supplier of soybean meal and refined vegetable oils.

AGP and its affiliated companies employ over 1,000 fulltime people across the United States. Join a team where each individual is dedicated to the continued growth and success of

Gold processing Plant: Based on abundant experiences on gold mining project, Prominer helps clients to get higher yield amp; recovery rate with lower running cost and pays more attention on environmental protection. Prominer supplies customized solution for different types of gold ore. General processing technologies for gold ore are summarized as below:

The largest AG mills in the world, theyre in diameter and 11m long with 28MW gearless motors. The ball mills, the second stage grinding equipment, are in diameter and long, each with two 7800 kW motors. 52 magnetic separators are used in each of the processing lines.

21/8/2020#0183;#32;The infrastructure for a processing plant that uses cyanidation typically costs 30 million, and is therefore, a barrier to entry for gold miners with smaller deposits that do not fit into the largescale economies of gold production. Gold recovery by cyanidation is also of environmental and safety concern as it relies on the use of toxic cyanide.

15/3/2018#0183;#32;The investment made in a gold processing plants, silver processing plants, as well as plants for recovery of other precious metals and rare earth minerals is

WhatsApp)

WhatsApp)