INSANE ROAD CONSTRUCTION TECHNOLOGIES THAT

07/04/2019#0183;#32;For copyright matters please contact us at: Warehouse https:///aeW8Sk

WhatsApp)

WhatsApp)

07/04/2019#0183;#32;For copyright matters please contact us at: Warehouse https:///aeW8Sk

Earthwork is one of the major works involved in road construction. This process includes excavation, material removal, filling, compaction, and construction. Moisture content is controlled, and compaction is done according to standard design procedures. Normally, rock explosion at the road bed is not encouraged. While filling a depression to reach the road level, the original bed is flattened

This is the lowest layer of the road construction, and is made of cement bound granular material containing crushed rock or gravel. This is the road foundation and it transfers the loads from above to lower layers, building up the strength of the road pavement. Capping Course. This is a layer of granular product from crushed rock quarry, and often, recycled material. It provides a construction

17/10/2016#0183;#32;The process of quarrying requires drilling and blasting. After the suitable method is applied the crushed rock is transported to the process facilities. There are many processing plants across the

23/05/2019#0183;#32;subscribe my channel .support and share, professional surveyor. Music provided by: No Copyright Songs Best Of Alan Walker Spectre [NCS Best Of]: http...

16/03/2017#0183;#32;Pavement design is the major component in the road construction. Nearly onethird or onehalf of the total cost of construction, so careful consideration should be taken in design of pavement. Type of pavements: Flexible pavement. Rigid pavement; Semirigid pavement; Factors which affect the selection of these pavements . Initial cost; Availability of good materials; Cost of

As the road construction systems are identical all through the globe, one can effortlessly develop rational cost estimates as soon as the prime conditioning factors are recognized, with the use of the figures obtained from the same type of road construction projects. With the aim of simplifying your task in figuring out forest road costs and for reasons of comparing costs, it is suggested to

the long run to install proper drainage structures and rock surfacing on a road that gets muddy and rutted every winter than to regrade the road surface every spring. UNDERSTANDING ROAD COMPONENTS Although roads vary in their configuration and design, they have common elements that affect their functionality and durability. Roads must create a flat surface for vehicle travel on sloped land. To

weathering process and key aspects of the road environment (eg climate) are radically different from those in temperate regions, where the great majority of the research and development of materials standards, specifications and construction procedures have originated. In the tropics and subtropics roads will tend to

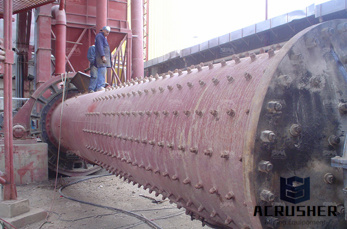

Removing the goldbearing rock from the ground is just the first step. To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravel. The gravellike material then enters rotating drums filled with

Stone quarrying is the multistage process by which rock is extracted from the ground and crushed to produce aggregate, which is then screened into the sizes required for immediate use, or for further processing, such as coating with bitumen to make bituminous macadam (bitmac) or asphalt. The process begins with a detailed threedimensional survey of the quarry face. This allows the explosives

03/08/2017#0183;#32;Follow these basic rules of gravel road construction and youll be on the right track. 1. Assess road use. Before you start the construction process, its important to consider the types of vehicles that will be using the road. This will help determine the ideal path and width of the road, as well as the required depth of the base material. For example, a gravel road that must support

26/10/2017#0183;#32;Please watch: quot;Concrete acceleratorsquot; https:// ~ A road surface or pavement is the durable surface material laid down

Sand in Road construction in the SADC Region is to provide practitioners with a good understanding of the engineering properties of one of the most abundant, naturally occurring materials found in the Southern African region sand so as to facilitate the more widespread use of this ubiquitous material in the construction of low volume roads. The need for the guideline has been

Drilling and blasting is the controlled use of explosives and other methods such as gas pressure blasting pyrotechnics, to break rock for is practiced most often in mining, quarrying and civil engineering such as dam, tunnel or road result of rock blasting is often known as a rock cut.. Drilling and blasting currently utilizes many different varieties of

The method and equipment used in road construction is an important economic and design factor in road location and subsequent design. A road to be built by an operator whose only equipment is a bulldozer requires a different design than a road to be built by a contractor equipped with hydraulic excavator, scrapers, and bulldozer. Table 38 lists common road construction equipment and their

The Process of earthworks is to excavate the existing land to a suitable level so that road construction may begin. The earthworks can take the form of either excavation in the form of cuts or the construction of embankments to carry an elevated highway. Normally in a road design project, both will be necessary and movement of earth from one part of the site to the next will be necessary. This

23/01/2012#0183;#32;Next, rock samples are taken through drill testing and analyzed. Geologists and mining engineers use these samples to determine if gold actually exists, the size of the deposit and the quality of gold in the ground beneath. This information is used to determine if enough gold exists under the surface to make mining worthwhile. Step #4 Type of mine. If its determined the amount and

The large pieces of ore (broken rock) are fed into a series of crushers and grinding mills to break down the ore into much smaller sized rock so that the gold can be more easily extracted. At this stage of the process, the ore is ground down to fine sandlike particles.

Heavy construction equipment are used for various purposes in large projects. Selection of different types of heavy equipment depends on the size of the work and economy of the project. These make construction process easier and faster. Types of Heavy Construction Equipment Different types of heavy equipment commonly used in the construction are as follows: Excavators []

WhatsApp)

WhatsApp)