What are main Types of Rolling mill? mech4study

This type of rolling mill consist three rollers arrange parallel to each other. In this machine the middle roller rotate in opposite direction of other two rollers. This machine is

WhatsApp)

WhatsApp)

This type of rolling mill consist three rollers arrange parallel to each other. In this machine the middle roller rotate in opposite direction of other two rollers. This machine is

15/6/2017#0183;#32;Four Types of Rolling Mills. In the past two articles we briefly outlined rolling mills, and also expounded on three different types. In this article, we will finish the series outlining the differences between a fourhigh rolling mill, cluster rolling mill, continuous mill and a planetary rolling mill.

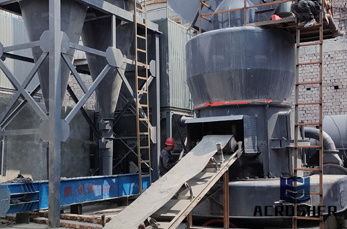

Types Of Vertical Roller Mill. Vertical roller mill is the equipment that provides grinding operation of materials needed by different industries, such as building materials, metallurgy and chemical industry. For different fineness and productivity, different vertical mills are needed to complete the production.

You can customize your vertical roller mill depending on what material you need reduced. Learn more about the different types of feeders that can be furnished to fit Williams roller mills. Or, contact the Williams team today to discuss your specific customization requirements for one of our roller mills.

A roller mill is a milling machine that gently and gradually reduces material to a smaller size. There are one or two pair of chilled cast iron rolls inside the machine. These rolls are lying parallel and are supported at each end by roller bearings. The back roll is in a fixed position and the front roll is movable to adjust the roll clearance.

Roller Mill Type AMRM. Minimum thickness of the hard layer of cast iron rollers is min 13 mm (Naminal:15mm) and the hardness is minimum 500 HB and are made in BALAGUERE of Spain. The rollers are grinded and fluted and balanced. The average linear speed of the rollers in BK is approximately m/s and in MI app. m/s.

Type # 1. TwoHigh Rolling Mills: The twohigh rolling mill consists of a twohigh stand with two horizontal rolls, placed exactly one over the other. In this type of mill, one or both the rollers are adjustable. In its operation, the metal is passed between the two rollers rotating at the same speed but in opposite direction.

Three Roller Grinding Mill Price In Malawi China Three Roller Mill manufacturers Select 2020 high quality Three Roller Mill products in best price from certified Chinese Oil Mill manufacturers Paint Grinding Machine suppliers wholesalers and factory on MadeinChinacom. type of type of rol

Tags Metal Processing Machinery, Rolling Mills; Four Types of Rolling Mills. In the past two articles we briefly outlined rolling mills, and also expounded on three different types. In this article, we will finish the series outlining the differences between a fourhigh rolling mill, cluster rolling mill, continuous mill and a planetary rolling mill.

2/5/2017#0183;#32;This type of rolling mill consist three rollers arrange parallel to each other. In this machine the middle roller rotate in opposite direction of other two rollers. This machine is used to reduce two times thickness in one pass.

Types of pulverizers mainly there are three types of pulverizer used in industry the slow speed mills like ball tube mills, the medium speed mills like bowl, ball and race, roller mills fall in this category, and the third type is the high speed impact m.

vertical roller type grinding mill . MPS vertical roller mill Gebr. Pfeiffer. The versatile MPS vertical mill with a fine tradition of quality grinding The MPS vertical roller mill built to last, reliable and energyefficient is the optimum .. wear parts of the grinding elements as is the case with any type of vertical mill.

Large Grinding Mills Of The Roller Type. The loesche mill also known as the disc roll mill is a special type of roller mill in which the grinding surfaces consist of two rollers assembled over a horizontal disc or table which rotates at a relatively low speed this design is particularly applicable to industrys present day demand for large capacity grinding mills

Roller mills accomplish size reduction through a combination of forces and design features. If the rolls rotate at the same speed, compression is the primary force used. If the rolls rotate at different speeds, shearing and compression are the primary forces used.

Raymond Mill. Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill. READ MORE. Vertical Roller Mill. Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment. types of vertical roller mills .

Jun 15, 2017 Tags Metal Processing Machinery, Rolling Mills; Four Types of Rolling Mills. In the past two articles we briefly outlined rolling mills, and also expounded on three different types. In this article, we will finish the series outlining the differences between a fourhigh rolling mill, cluster rolling mill, continuous mill and a planetary rolling mill.

Since 2007 PJSC TYAZHMASH jointly with German partners has been developing and manufacturing mills of TBM type medium speed mills with toroidal rollers Mills are designed for coal semianthracites lean coal lignite grinding with predrying up to pulverized

WhatsApp)

WhatsApp)