Pulverizer Wikipedia

Pulverizer Wikipedia

WhatsApp)

WhatsApp)

Pulverizer Wikipedia

process of pulverizing of coal classifier in somalia. process of pulverizing of coal classifier,PROCESS FOR PULVERIZING COAL TO ULTRAFINE SIZE Dec 17 1974 A process for pulverizing coal to ultrafine size of a few microns comprising conveying the coal through successive pulverizers with an inert gas separating the ultrafine coal from the inert gas cooling and recycling the inert gas and producing

process of pulverizing of coal classifier . pulverizing coal burning system in china 46 views. process of pulverizing of coal classifier. pulverizing coal burning system in china. gt;gt; ask price;get price

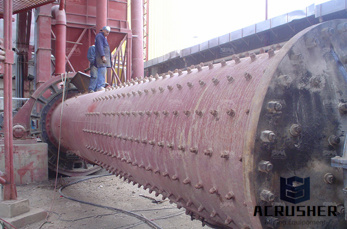

classifier coal screen supremewheels. The crushed coal is further passed over magnetic separator which removes pyrites and tramp iron. The further equipment through which coal is passed before passing to pulverizer are already shown in figure. a) Ball mill pulverizing . Ball and Race mill pulverizing. a) Ball Mill .

classifiers in pulverizers. classifier of coal pulverizers A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating

process for pulverizing coal to ultrafine size. stractural arrengement of coal mill pulverizing pdf. Coal Pulverizing Mills EquipmentMine (2) vertical coal pulerizing mill, theory application service (tas) model 42b with 350 hp vertical vbelted electric motor drive. mill has a 42'' diameter 5stage rotor and is designed to mill coal to 200 mesh for kiln feed at the rate of 6 tph. systemget price

process of pulverizing of coal classifier,PROCESS FOR PULVERIZING COAL TO ULTRAFINE SIZE Dec 17 1974 A process for pulverizing coal to ultrafine size of a few microns comprising conveying the coal through successive pulverizers with an inert gas separating the ultrafine coal from the inert gas cooling and recycling the inert gas and producing makeup inert gas by water scrubbing and alkaline

About 30 of these are mineral separator, 4 are sand washer, and 1 are other mining machines. A wide variety of coal spiral classifier. Prices / Quote. Classifier For Chrome Processing. Classifier for chrome processing Mine EquipmentsCoal mill pulverizer in thermal power plants SlideShare 17 Nov 2012 During the pulverization process the.

coal crushing and pulverizing system The coal pulverizing system manufacturer must be a full and active participant in the training effort, with utility coordination of the various complimentary system manufacturers (, combustion controls, etc.) to assure an integrated pro price. coal crushing and pulverizing system.

A fuel coal processing machine as set forth in claim 7, and a size classifier means, wherein the purified coal passing above said splitter blade means on the way to said combustor is carried through said size classifier means by said high velocity air stream, and whereby sufficiently reduced coal is carried to said combustor and oversize coal particles are recirculated back to said pulverizer

Reading Coal Geology Simple Book Production. Instead of pulverizing the coal and burning it directly as fuel in the steamgenerating boiler, the coal can be first gasified (see coal gasification) to create syngas, which is burned in a gas turbine to produce electricity (just like natural gas is burned in a turbine).

process of pulverizing of coal classifier in israel. We are here for your questions anytime 24/7, welcome your consultation. Get Price. A system for pulverizing coal to be burned in a furnace where nearly all of the coarse ash particles are removed from the coal prior to its introduction to the furnace The system includes a pulverizing mill

#0183;#32;During this process, the coal particles become smaller due to attrition and collisional forces. Then, the pulverized coal particles move into the classifier volume (4). In the classifier volume, the gas and coal particle mixture exits the pulverizer at a velocity of approximately 3035 m/s.

#0183;#32; The circulating air is also used to classify the pulverized coal product prior to carrying it to the burners. The classifier, located on the top of a mill returns the oversize material back to the pulverizer but allows the propersized material to pass out of the mill to the burners. classifiers are critical in providing the desired quality of pulverized coal with the

WhatsApp)

WhatsApp)