The Dorr Mill Store

Someone is always ready to assist you at the Dorr Mill Store. Just give us a call at 800846DORR () Or email us: .(JavaScript must be enabled to view this email address)

WhatsApp)

WhatsApp)

Someone is always ready to assist you at the Dorr Mill Store. Just give us a call at 800846DORR () Or email us: .(JavaScript must be enabled to view this email address)

PATTERSON Urethane Lined Pebble Mill Door for 60 dia. PATTERSON Pebble Mill Top Side As above Bottom Side 18quot; Babitted Replacement Bearings for PATTERSON Ball Mill. 12quot; Babitted Replacement Bearings for PATTERSON Ball Mills. Top view of Discharge Grid for Steel Ball Mill.

Modelling mineral size reduction in the closedcircuit ball mill at the Pine Point Mines concentrator. International Journal of Mineral Processing 1981, 8 (1), 6178.

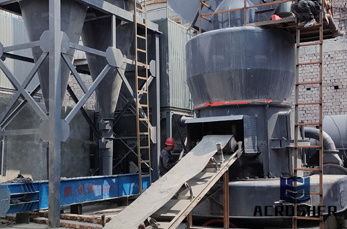

Ball Mill Spare Parts We can provide professional OEM Service for large cement equipment steel castings. Those cast components, ball mill spare parts, can be supplied in the following conditions: Heat treatment: Normalized, Normalized and Tempered, Quenched and Tempered Machining: Rough machined, Semifinished machined, Finished machined NonDestructive Testing: MT, UT, PT (in

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as it rotates and falls back into the toe of the mill when the force of gravity exceeds friction and centrifugal forces.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Grinding With Metal Balls. Industrial Mill, Ball Mill, Mill At The Factory Download From Over 146 Million High Quality Stock Photos, Images, Vectors, Stock Video. Sign up

Ball mill internal Measure m diameter x 6 mt length external Measure mt x mt. Two access doors; Two inspection ports; complete and reinforced Bearings lateral reinforcements approximate weight of 21 ton steel smooth inter...

Ball Mill Door Flap. We are offering ball mill door flap. we bring forth comprehensive heat resistant steel castings for our valuable clients. Our heat resistant steel castings have been consistently appreciated by our clients and we cater to their needs with the best of our efforts. material

Industrial Solutions. Grinding and drying for a wealth of applications Our customers not only benefit from the decades of experience we have gained through successfully commissioning more than 2,200 ball mills, but also from our comprehensive scope of services, ranging from maintenance and OEM spares procurement to the

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

Table of ContentsTypes of Grinding Mill ManufacturedROD MILLSPEBBLE MILLSSelecting Wet or Dry Grinding MillHow much grinding power is neededSAG Mill vs Ball MillMill

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

Ball mills can grind in either a wet or a dry environment. In addition to the traditional rotatingdrum type, some models use planetary, vibrational or centrifugal motion. How to choose. Choice of ball mill will depend on the type and quantity of product to be ground.

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

#0183;#32;Learn more about these metrics Article Views are the COUNTERcompliant sum of full text article downloads since November 2008 (both PDF and HTML) across all institutions and individuals. These metrics are regularly updated to reflect usage leading up to the last few days. The Altmetric Attention Score is a quantitative measure of the attention that a research article has received online.

WhatsApp)

WhatsApp)