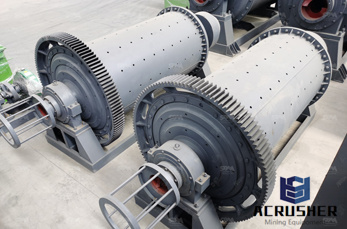

slag grinding ball mill

Slag Mill. Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building

WhatsApp)

WhatsApp)

Slag Mill. Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building

To make full use of the original clinker grinding plant, the active mixing material with poor easy grinding ability water slag is pulverized separately, stored in the slag powder storehouse, and the microcomputer is used to prepare cement proportionally, which can achieve reasonable particle gradation and the effect of separate grinding.

Blastfurnace slag cement may include up to 70% ground granulated blast furnace slag. See cement. Gypsum and calcium carbonate are relatively soft minerals, and rapidly grind to ultrafine particles. Grinding aids are typically chemicals added at a rate of

Cement Plant, Slag Grinding Plant, Steel Mill: Capacity: 1178 t/h: Motor Power: 954500 kW: Fineness: cm#178;/g: Overview. Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory

In the wet process, first of all, the newly quarried limestone is crushed into smaller pieces. Then in the ball or tube mill, it is mixed with clay or shale with water to form a slurry. The slurry is a liquid of creamy consistency with a water content of about 35 to 50 percent, wherein particles, crushed to the fineness are held in suspension.

Cement Plant, Slag Grinding Plant, Steel Mill: Capacity: 1178 t/h: Motor Power: 954500 kW: Fineness: cm#178;/g: Overview. Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement

Rawmill Wikipedia. A raw mill is the equipment used to grind raw materials into quot;rawmixquot; during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large

Improvements in slag grinding efficiency was developed and implemented with existing cement manufacturing technology. Descriptions . Improvements in the grinding process to produce fine granulated blast furnace slag suitable for use in the production of blast furnace cement was achieved with pregrinding and vertical mill technologies used in

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used

This slag ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics. Besides, it can also used in dry and wet grinding for all kinds of ores and other grindable materials.

Blastfurnace slag cement may include up to 70% ground granulated blast furnace slag. See cement. Gypsum and calcium carbonate are relatively soft minerals, and rapidly grind to ultrafine particles. Grinding aids are typically chemicals added at a rate of % that coat the newly formed surfaces of broken mineral particles and prevent reagglomeration.

working process of slag mill in cement plant Cement mill Wikipedia A cement mill or finish mill in North American usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills

Which Kind Of Grinding Mill Is Suitable For Slag. SBM LM vertical mill can be used for grinding slag. Usually, vertical mill for cement and concrete production in the construction industry can meet

Slag is mainly used for the production of cement, either as a cement mixture, can also be made nonclinker cement. After fine grinding blast furnace slag can be used as the main raw material for the production of slag powder. It can replace silicon bath soil insulation packing and save cost. It can be used for the production of slag bricks and wet grinding slag concrete products. It used for thermal insulation

grinding mills and complete plants that are widely used in Large nonmetallic mineral powder, limestone desulfurization, heavy calcium processing, pulverized coal preparation and other fields.

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process. The concept of M and Srollers was established in 1992, which is one of the most cost effective and successful LOESCHE innovations.

Oct 23, 2015#0183;#32;Multicompartment ball mills and air separators have been the main process equipments in clinker grinding circuits in the last 100 years. They are used in grinding of cement raw materials (raw meal) ( limestone, clay, iron ore), cement clinker and cement additive materials ( limestone, slag, pozzolan) and coal.

These mills are used to grind cement raw materials and cement or granulated blast furnace slag (Figure 1). Structure and maintenance of Pfeiffer''s MPS vertical roller mill The structure of the MPS BC series, to which all mills producing cement or BFS powder belong, basically corresponds to that of the MPS vertical roller mills that have been used for cement raw material and coal grinding since the 1960s (Figure 2).

This slag ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory

The mill is equipped with an external material recirculation allowing the reduction of pressure loss in the mill. It can also be used for emptying the mill in case of maintenance. When grinding granulated blastfurnace slag, the iron particles contained in the slag can be discharged.

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both,

WhatsApp)

WhatsApp)